Copper

The many unique and beneficial properties of copper are highly valued in the world today. Historically, copper is one of the oldest materials used by man and can illuminate parts of our great history throughout civilised times. The production and use of copper are also vital parts of our economy.

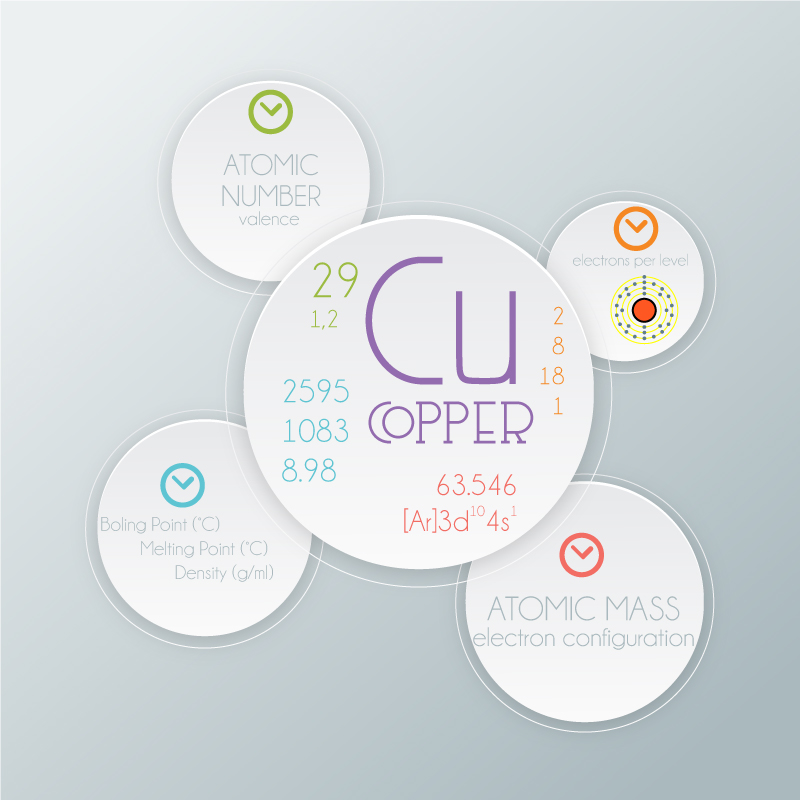

The copper element is in the same periodic table group as silver and gold. Therefore, it is relatively inert against chemicals. Copper and copper compounds give a greenish color to a flame.

Due to the chemical properties of copper, the corrosion process is very slow. The corrosion resistance of copper and copper alloys is based on their ability to form stable compounds that provide some protection from corrosive attack. When exposed to the atmosphere, protective layers of oxides and poorly soluble basic salts form on the surface of copper and copper alloys.

The primary mechanical properties of copper – hardness, strength and ductility – determine its condition. Copper can be supplied in a range of conditions from annealed (soft) to fully hard, which is obtained by cold working. The ductility of fully cold worked copper is much less than in the annealed condition with a value of 2% elongation. The strength and hardness of copper can also be increased by alloying, but this results in a decrease in electrical conductivity.

The generation, transmission and use of electricity has transformed the modern world. This has been made possible by copper (of at least 99.9% purity), which has the best electrical conductivity of any common metal – one of the more well-known physical properties of copper. It is available in wrought form as wire, cable, strip and busbars and as castings for such components as electrical switchgear and welding equipment.

Imagine a world without electricity: no lighting, TVs, DVD players, iPads, electric kettles, mobiles, washing machines, fridges, vacuum cleaners, computers, cars, buses, electrified railways, underground transport systems or trams.

A high-purity copper wire harness system carries current from the battery throughout a vehicle to equipment such as lights, central locking, onboard computers and satellite navigation systems. Electric motors, which are wound with high conductivity wire, are used in many of these devices. The average car contains about 1 km of wire.

Copper is a good conductor of heat (about 30 times better than stainless steel and 1.5 times better than aluminium). This leads to applications where rapid heat transfer is required such as heat exchangers in air conditioning units, vehicle radiators, heat sinks in computers, heat sealing machines and televisions, and as water-cooled furnace components. Good-quality spark plugs have a central copper electrode to enable heat to be removed and prevent overheating. The best quality saucepans are copper bottomed to ensure uniform, rapid heating.

Copper can be readily joined by brazing, soldering, bolting or adhesives. In industry, this is very useful for plumbing pipework and joining busbars, which are vital elements of power distribution systems. Elsewhere, it is also an important feature for artists crafting sculptures and statues, and for jewellery makers and other artisans working with this beautiful metal.

History of copper

The element copper has been an essential material to man since the prehistoric time. In fact, one of the major 'ages' or stages of human history is named after a copper alloy: bronze.

In the history of copper, one can follow human progress. Copper was the first metal used by man in any quantity. The earliest workers in copper soon found that it could be easily hammered into sheets and the sheets in turn worked into shapes which became more complex as their skill increased.

After the introduction of bronze, a wide range of castings also became possible. Many of the illustrations on this site show man's strides in metal-working, culminating in the priceless inheritance of the Renaissance craftsmen. But copper and its principal alloys, bronze and brass, have always been more than a means of decorative embellishment.

Although iron became the basic metal of every Western civilisation from Rome onwards, copper metals were used when strength and durability properties were required. The ability to resist corrosion ensured that copper, bronze and brass remained as both functional and decorative materials during the Middle Ages and the successive centuries through the Industrial Revolution and on to the electric innovations of present day.

Main applications

Copper is among the best conductors of electricity and heat, so it is hardly surprising that about 60% of total copper use is for energy and renewables, sustainable energy solutions. Weight for weight, outside precious metals, copper is the best conductor of electricity and heat.

At the forefront of sustainable energy solutions, copper is used in high, medium and low voltage power networks, and copper conductivity is considered to be the standard by which other conductors are measured.

Blister copper is 96-99% pure, but there is a way to purify it further, through a technique called electrolysis. The unique combination of strength, ductility and resistance to creep and corrosion establishes this non-ferrous metal as the preferred and safest conductor for wiring in buildings. As an essential component of energy-efficient motors and transformers, it is used in a multiplicity of applications in manufacturing industries, all forms of transport and the domestic environment.

Copper's conductivity is almost twice that of aluminium, which makes copper the material of choice for high energy efficiency applications.

Copper wire has long been the preferred conductor material in the majority of cables used for power and telecommunications. Having high conductivity combined with ductility that makes it easy to draw down to close-tolerance diameters, it can also be readily soldered to make economic, durable connections. It is compatible with all modern insulation materials, but its good oxidation resistance means that it can also be used without any surface protection.

Copper used for the manufacture of transformer windings is in the form of wire for small products and strip for larger equipment. For small products, such as magnet wire, the wire must be strong enough to be wound without breakage, yet flexible enough to give close-packed windings. Strip products must be of good surface quality so that insulating enamels do not break down under voltage. Good ductility is essential for the strip to be formed and packed, and good strength is needed to withstand the high electro-mechanical stresses set up under occasional short-circuit conditions. The properties needed for motor windings are similar to those needed for transformers, but with the additional requirement to withstand mechanical vibration and centrifugal forces at working temperatures.

The primary use of copper in wind power technologies is in the coil windings in the stator and rotor portions of the generator, in the high-voltage power cable conductors, transformer coils and earthing.

Contemporary architecture also benefits from copper, because it complements commonly-used materials such as brick, wood, stone and glass, and can be used for buildings with traditional or modern styles.

Copper is a beautiful material: no other metal, except gold, has a colour; when exposed to the environment its shiny red becomes brown and then progresses to its distinctive green patina. Industry is now able to provide pre-oxidised and pre-patinated sheets to architects, who appreciate the availability of forms and their ability to be easily shaped.

Copper, and copper alloys, give performance, durability (100+ years), a range of colours, forms and textures, all in a natural, 100% recyclable material.

Copper offers the best electrical conductivity of any metal (except silver, which would be prohibitively expensive for common applications). It is also inherently antimicrobial, meaning it will rapidly eliminate disease-causing germs that settle on its surface.

When alloyed with other metals, copper can also provide excellent corrosion resistance both in air and water, superb durability and malleability, and a wide range of colours to suit different aesthetic requirements. The red metal is ideally suited for hand hammered copper applications, and has made numerous design festival showings

An important consideration for any designer, architect or manufacturer when selecting materials is recyclability, and all copper alloy is fully recyclable, without loss of properties.

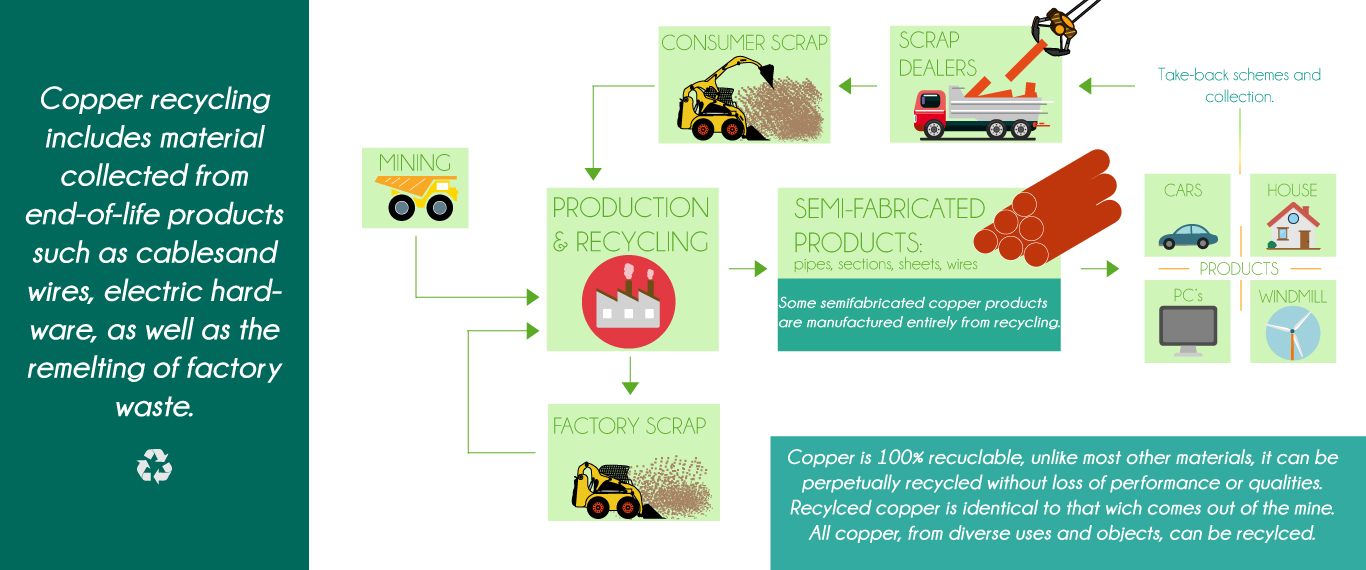

Recycling

Copper can be fully recycled and reused again and again, without any loss of performance. Copper recycling and waste management have become an important part of the supply chain, keeping resources local, creating local jobs, saving on landfill site space and incentivising the recycling of other materials.

Copper is omnipresent in the equipment modern life depends upon more and more, namely high-tech products, electrical installations, engines, solar systems and smart buildings.

Mine production remains vital in order to meet this growing demand. Ensuring that sufficient copper will be available to meet society’s future needs will require increased levels of recovery and recycling, as well as substantial investments in mining.